close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-14 Origin: Site

On scorching summer days, the cool breeze inside the car dispels the heat; in the biting cold of winter, the warm air brings a sense of comfort; during long drives, the fresh air revitalizes the spirit—all of this is made possible by the quiet operation of a car air conditioning system. This seemingly simple device is a sophisticated “climate control system.” Today, let us uncover its mysteries together.

The car air conditioning system is far more than a simple “cooling” or “heating” tool; it fulfills three crucial missions:

The cooling system is the “temperature-lowering marvel” of summer, capable of rapidly reducing the cabin temperature and transforming stuffy air into a comfortable, cool breeze. More importantly, it regulates temperature, humidity, airflow, and cleanliness to create an optimal microenvironment for occupants, thereby reducing travel fatigue and indirectly ensuring driving safety.

The heating system is a “warmth guardian” in winter. In addition to providing heat to raise the interior temperature, it has a crucial function: defrosting and demisting. During winter, when there is a significant temperature difference between the interior and exterior of the vehicle, the windows are prone to frost and fog. The heating system increases the temperature of the glass, quickly removing these visual obstructions to ensure driving safety.

The ventilation system is akin to the vehicle's “respiratory system,” continuously introducing fresh air into the cabin while expelling contaminated air mixed with dust, carbon dioxide, and harmful engine exhaust gases. During cold seasons, it also coordinates with the temperature control system to ensure that the incoming fresh air maintains an appropriate temperature.

The components of a vehicle's air conditioning system vary depending on the type of power source.

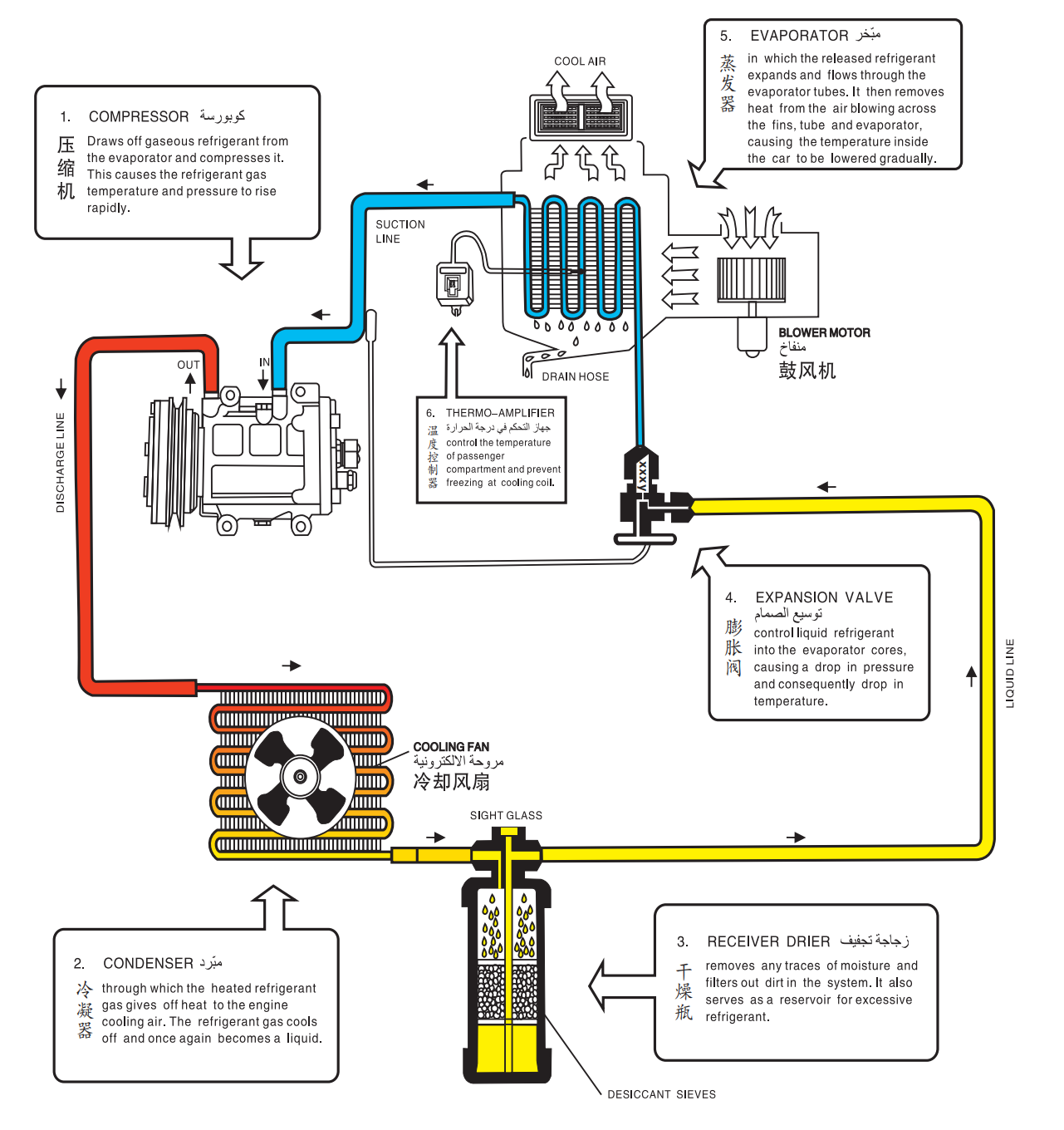

The cooling system of a traditional gasoline-powered vehicle consists of a compressor, an electromagnetic clutch, a condenser, and an evaporator, functioning like a precise “thermal transport team.” The system is divided into a high-pressure side (compressor output side, condenser, etc.) and a low-pressure side (evaporator and compressor input side), with each component performing a specific function.

Hybrid vehicles use an electric compressor combined with components such as a refrigerant shut-off valve for the power battery, balancing energy efficiency and cooling performance.

Differences in the heating system are even more pronounced: internal combustion engine vehicles rely on the engine radiator as a heat source, with core components including the heater core, blower, and control switch, effectively “utilizing engine waste heat for heating”; pure electric vehicles are equipped with positive temperature coefficient (PTC) heaters, which use high-voltage electricity to heat coolant, then transfer heat through the heating core, acting as “electricity-driven heating experts.”

The ventilation system is a “common configuration” for both traditional and new energy vehicles, primarily consisting of a blower, damper servo motor, air outlets, and ducts, which are responsible for air delivery and distribution.

Whether in traditional vehicles or new energy vehicles, the refrigeration system follows the basic principle of “vaporization and heat absorption.” The refrigerant (commonly R-134a) completes the cycle of “compression-condensation-expansion-evaporation” in a closed system.

- Compression process: The compressor compresses the low-temperature, low-pressure gaseous refrigerant into high-temperature, high-pressure gas

- Condensation process: The high-temperature, high-pressure gas releases heat in the condenser, transforming into a medium-temperature, high-pressure liquid

- Expansion process: The liquid refrigerant passes through the expansion valve, causing its pressure to drop sharply and transforming it into low-temperature, low-pressure wet vapor

- Evaporation process: The wet vapor absorbs heat from the vehicle interior in the evaporator, vaporizing into a gas and completing the cooling process

The cooling principle of new energy vehicles is similar, except that the compressor is driven by high-voltage electricity, which aligns more closely with energy-saving and environmentally friendly concepts.

The warm air in gasoline-powered vehicles is similar to an “engine waste heat recovery system”: hot water from the engine radiator flows through the warm air radiator, and the blower blows cold air over the surface of the radiator, causing the air to absorb heat and become warm air that is then delivered into the vehicle.

New energy vehicles function like an “electric water heater”: PTC heaters use high-voltage electricity to heat the coolant. The high-temperature liquid enters the heating core, where it exchanges heat with the air to produce warm air. This process does not rely on an engine and is entirely powered by electricity.

The ventilation system controls the direction of airflow by opening and closing the air vents, offering five airflow modes: face (dashboard vents), dual (dashboard + foot vents), foot (foot vents), mixed (foot + front windshield), and defrost (front windshield vents). In the automatic mode, the system automatically selects the appropriate mode based on the environment. It can also be manually switched using the “MODE” button to adjust the airflow direction as needed.

Refrigerant oil is the “lifeblood” of the air conditioning compressor, serving four primary functions: lubrication to reduce wear, sealing to prevent refrigerant leakage, cooling to protect components, and assistance in energy regulation. When using refrigerant oil, note the following: Only use the manufacturer-specified type; do not mix different types of oil. Avoid prolonged exposure to air (refrigerant oil easily absorbs moisture). The amount added should be strictly controlled, as excessive amounts can reduce the cooling efficiency. The oil quality should be checked before adding, and the system should be thoroughly cleaned if it appears blackened or contains carbon particles.

Refrigerant oil is the “lifeblood” of the air conditioning compressor, serving four primary functions: lubrication to reduce wear, sealing to prevent refrigerant leakage, cooling to protect components, and assistance in energy regulation. When using refrigerant oil, note the following: Only use the manufacturer-specified type; do not mix different types of oil. Avoid prolonged exposure to air (refrigerant oil easily absorbs moisture). The amount added should be strictly controlled, as excessive amounts can reduce the cooling efficiency. The oil quality should be checked before adding, and the system should be thoroughly cleaned if it appears blackened or contains carbon particles.

Additionally, when cleaning the air-conditioning system, avoid using water, corrosive, or flammable/explosive solvents. It is recommended to use specialized cleaners, such as R-141b or heptane, to keep the car's air conditioning system in optimal condition.

The car air conditioning system acts like a thoughtful “invisible butler,” working through precise component collaboration and scientific principles to create a comfortable and safe driving environment. Understanding its operating mechanism not only helps us use this system more effectively but also enables us to quickly identify issues when they arise, ensuring every journey feels like “spring all year round.”

Partner with ESIA — Quality You Can Trust

With over a decade of experience, Guangzhou ESIA Air-Con is your trusted partner for premium auto air conditioning parts. Whether you need reliable standard products or customized solutions, we deliver excellence at competitive prices — backed by responsive service and global logistics.

Join our global clients from Southeast Asia to the U.S. — let’s build a win-win future together.